Design & Prototype of 60mhz LE Filter Finishing & Testing Equipment

Form Lab X Saras Technology

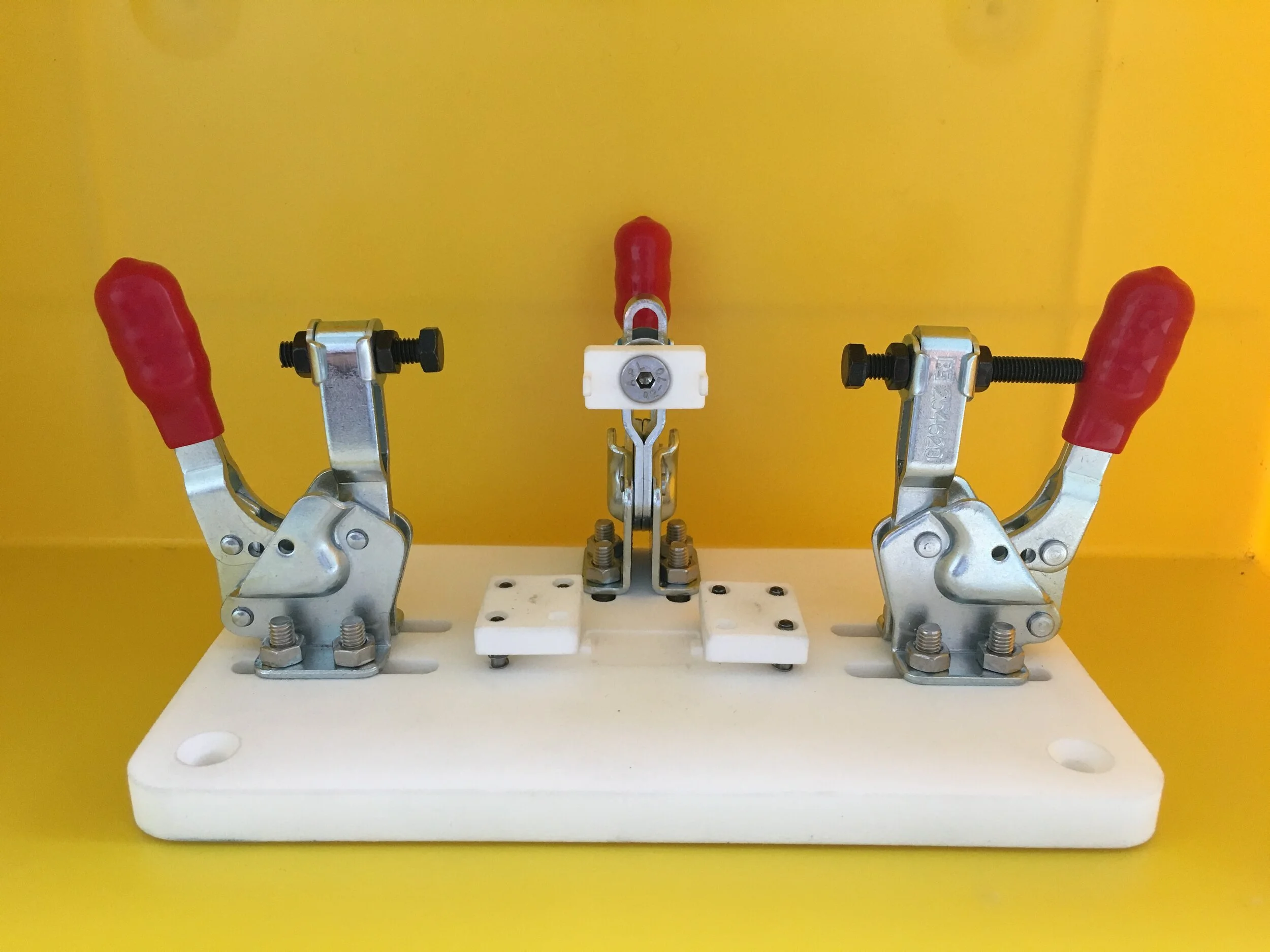

Lumped Element Filter Feed-Thru Pin Forming Jig

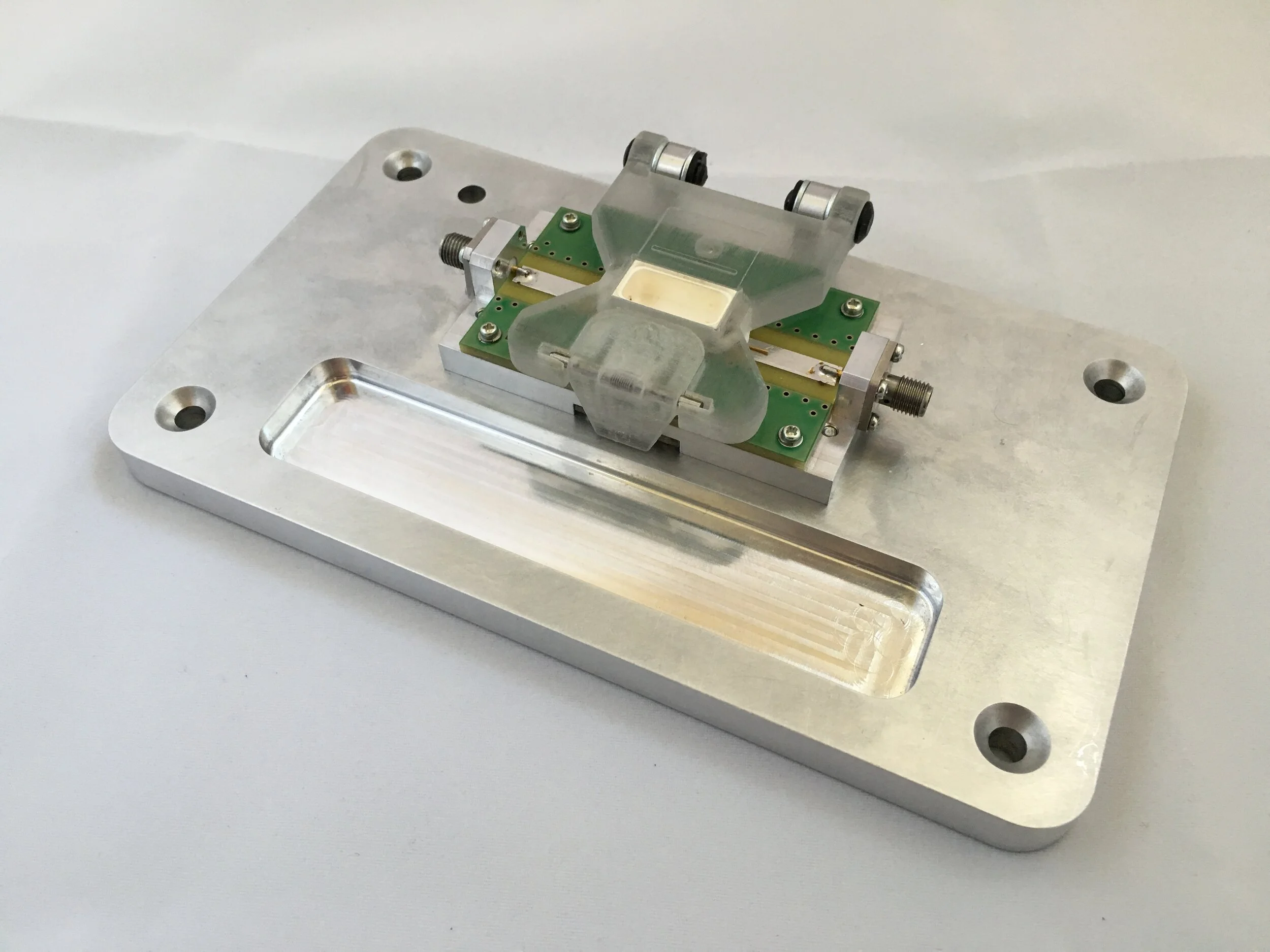

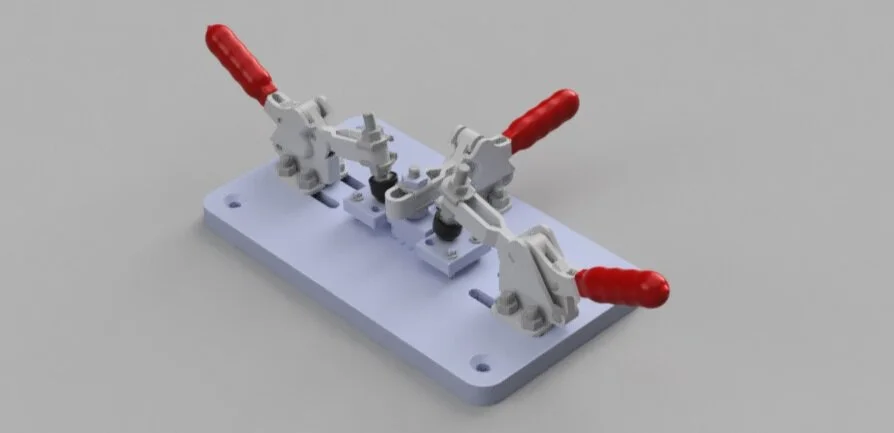

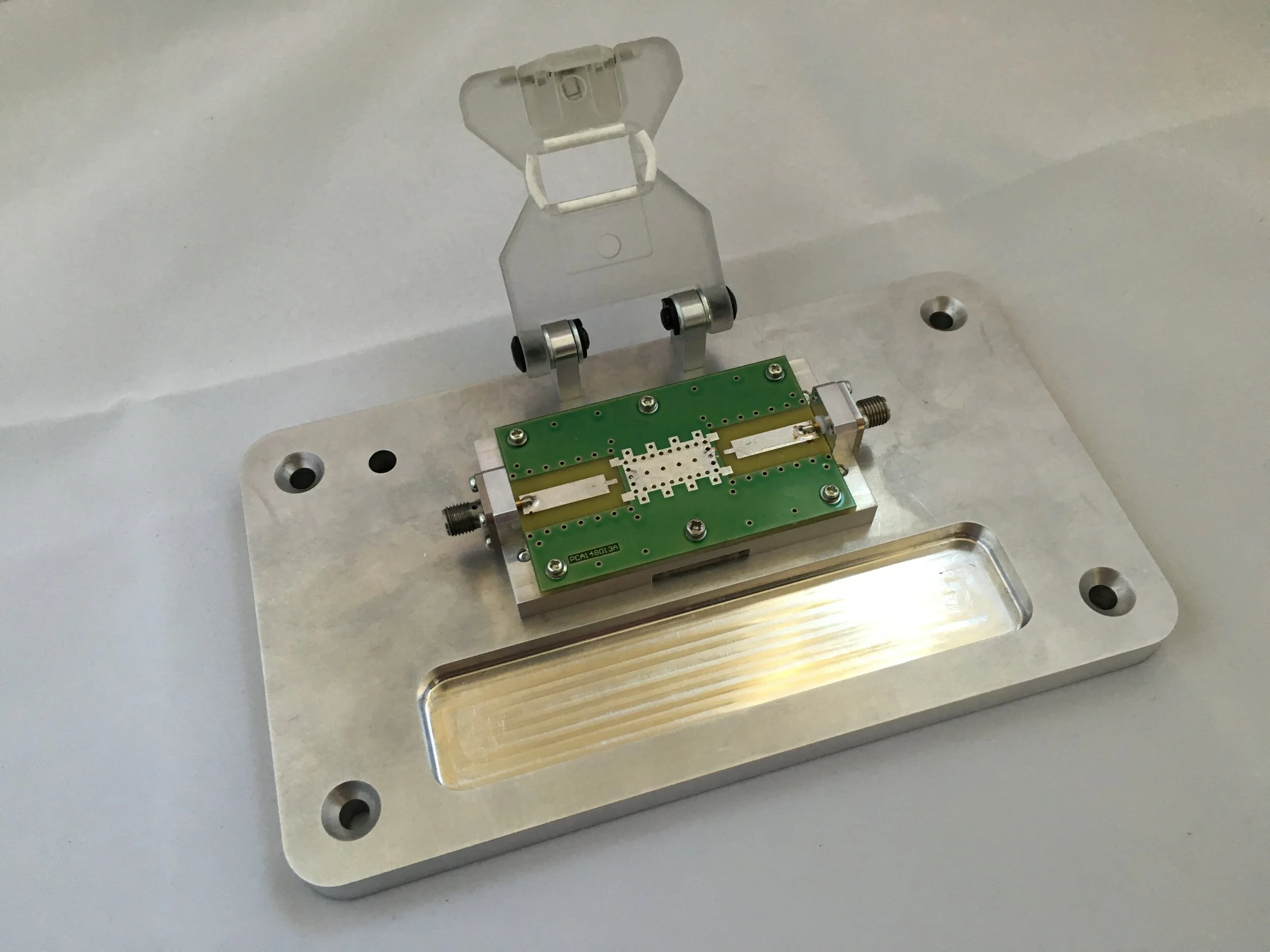

Lumped Element Filter Low-Cost Production Test Jig

In 2016, Form Lab worked with Saras Technology to aid in the design & prototype manufacture of low-cost 60mhz lumped element (LE) filter finishing & testing equipment. Our project brief was to develop & test two key mechanisms, a finishing tool for finishing the I/O pins of the Saras 60MHz filter, and a second tool that would allow for testing & tuning of the finished filter. The tools needed to be modular to allow the user to interchange modules depending on the current task, as well as allow scope for future design changes.

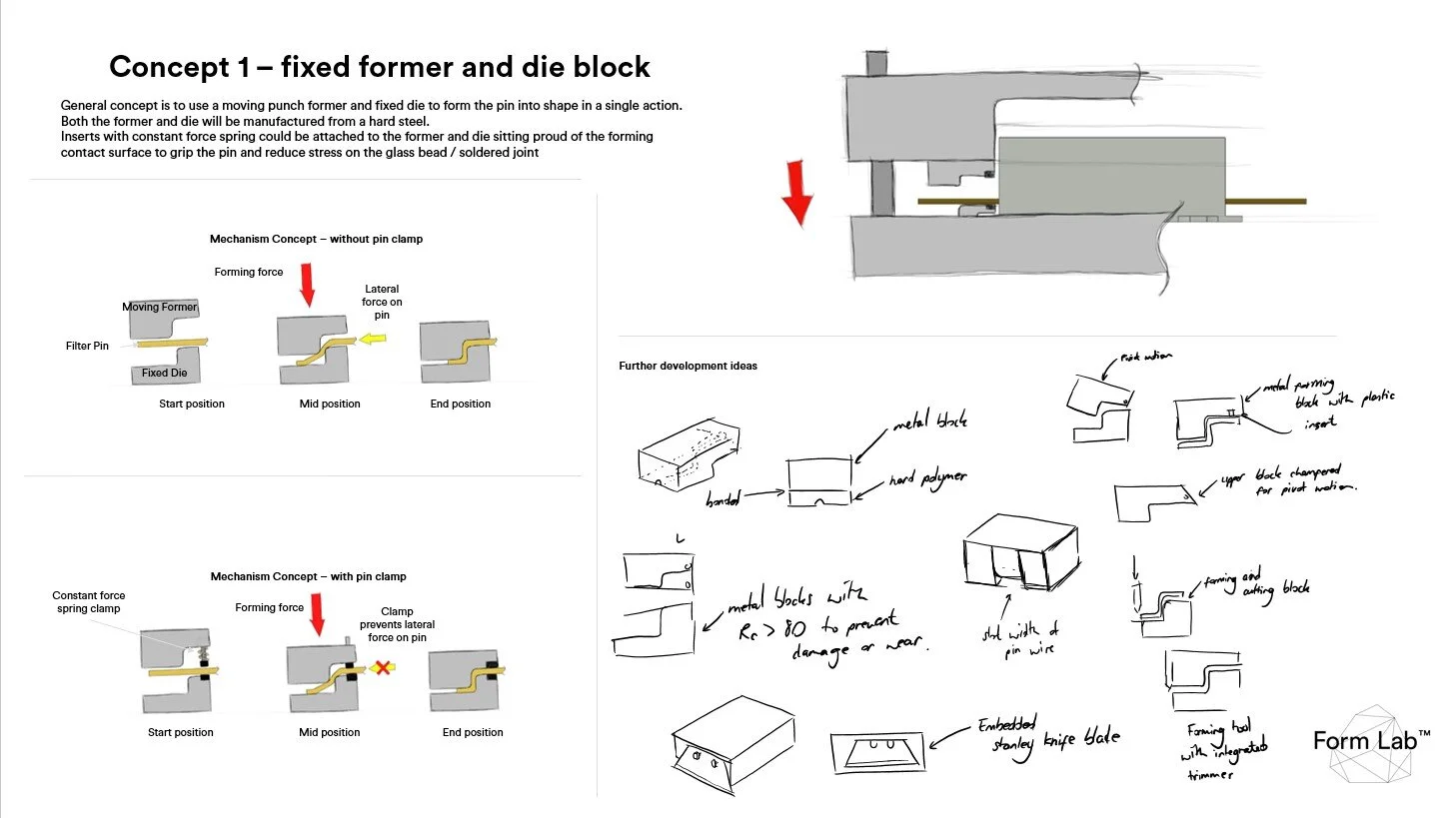

We produced a series of sketch concepts and CAD model prototypes, starting with rough sketches detailing different design ideas we had, and the potential pro’s and con’s to each design. We also started to map out how we might test these ideas, and what time, materials and resources this testing might require. Above is a sample of some of the initial sketch work we put together, before going back to the client to discuss what we had produced and what they thought of our initial proposals.

We also ran simulations using FEA on the Saras 60 MHz filter. This helped us understand the clamping precision of the filter assembly, and what sorts of clamping forces the housing could withstand without damage from our tool’s mechanisms when the component was being finished and tested. This is often a key part of our design process, as it helps ensure there are less issues in the physical prototyping phase, where having to iterate a design multiple times to get the tolerances correct can often prove both expensive and time consuming, especially if large numbers of different prototypes need to be manufactured.

Testing the non-marring clamping interface.

Testing the sprung return latch mechanism.

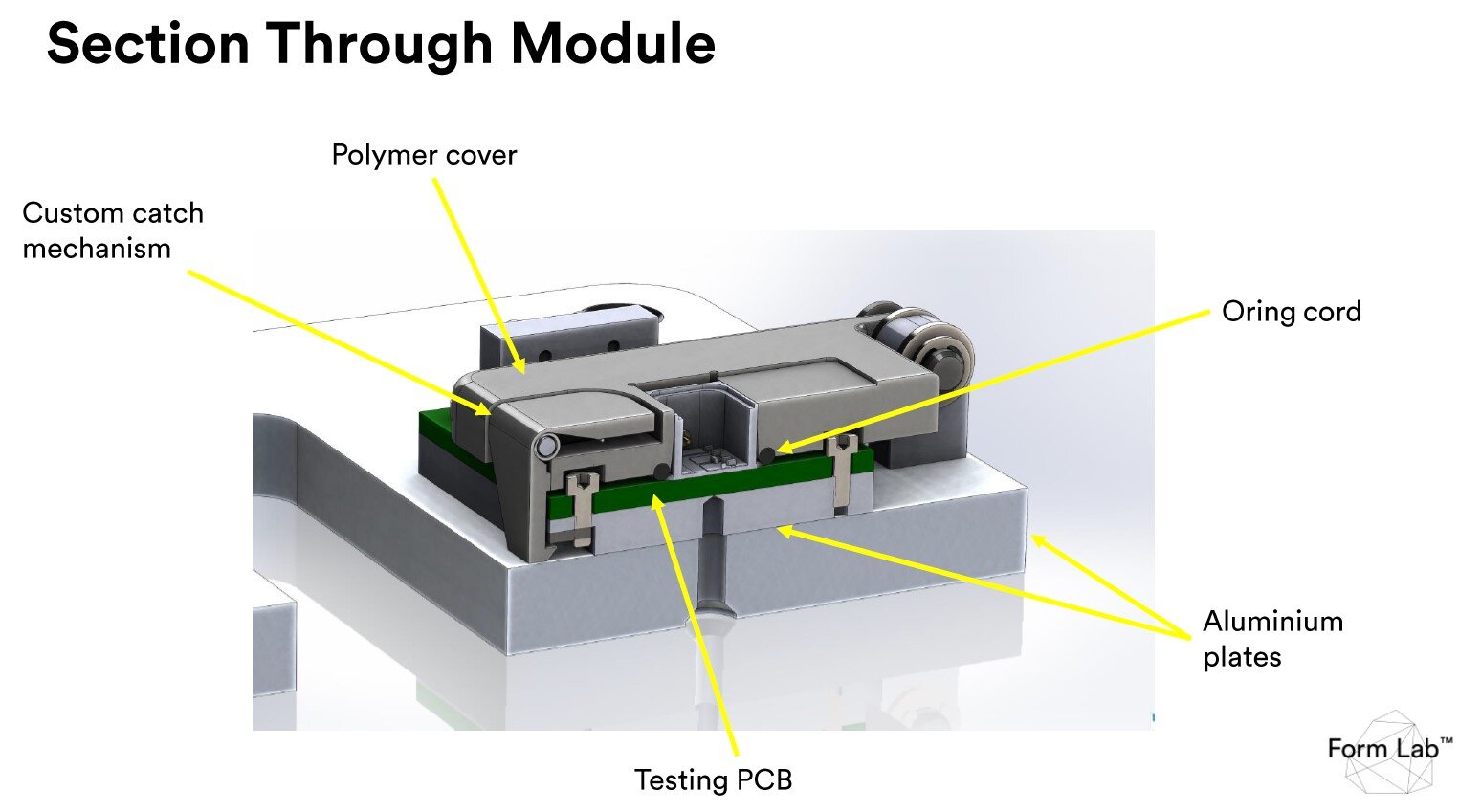

Form Lab worked on the project from concept generation through to producing the final production tools. This also included creating detailed CAD models of the final design, including technical drawings for both tools, as well as detailed 3D CAD files & renderings to show how the final physical prototypes would look and operate.

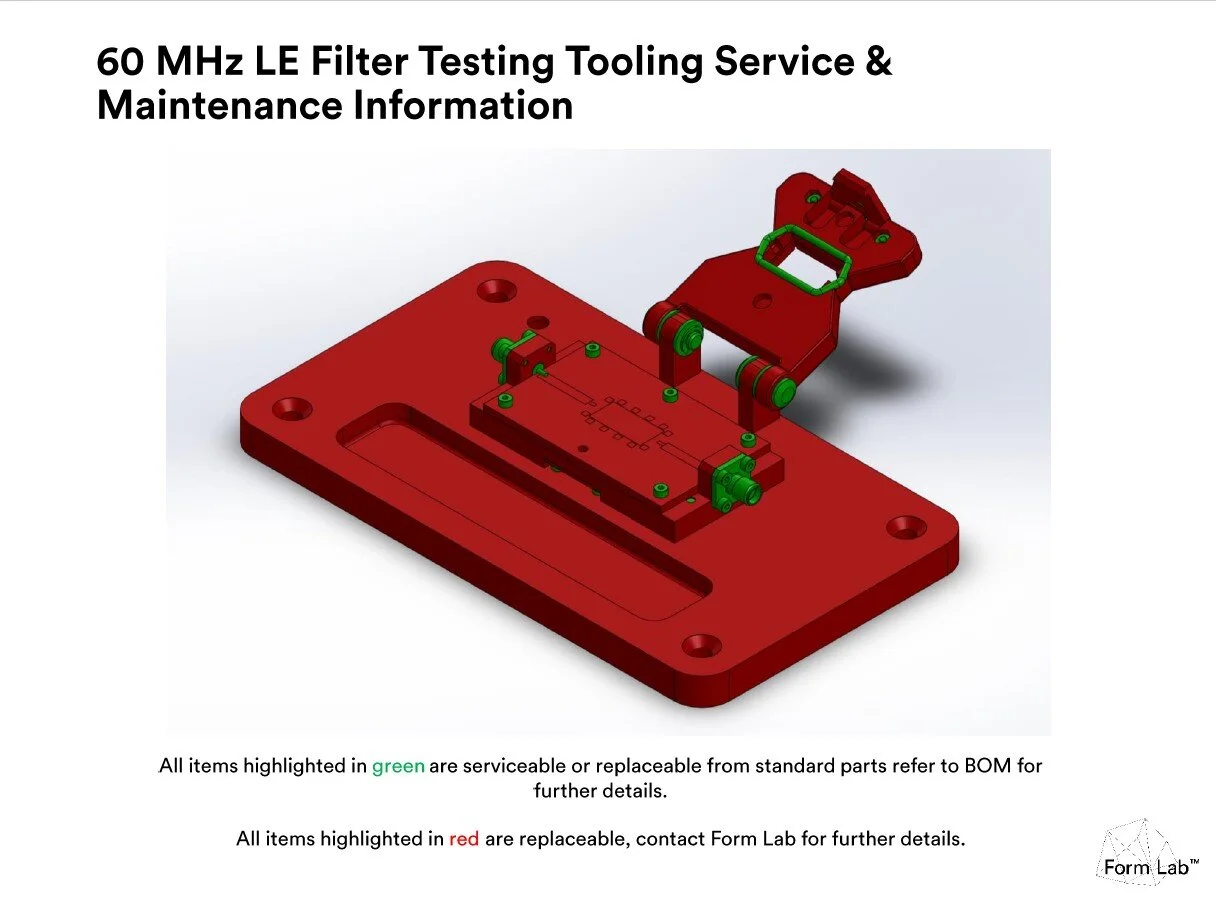

Form lab also produced an instruction & service manual to go with the designs we had put together. The manual provided operator instructions for both the finishing & testing tool, as well as maintenance information for both tools. The maintenance information also highlighted which components were standard components the client could source themselves for repairs, and which components where custom designed by Form Lab, with details on how to contact us for replacement components.

We finished the project by delivering the finished production versions of each tool, alongside providing finished technical drawings, a bill of materials, 3D CAD files and maintenance & service information for both tools to the client. This was a great project showing the multiple design capabilities we have here at Form Lab, and how we can take a brief from concept generation, all the way through development and testing, to reaching a final working prototype.

Interested to see if Form Lab can help with your project? Get in touch to see if we can help!